It seems a little early to muse about this, but oh well.

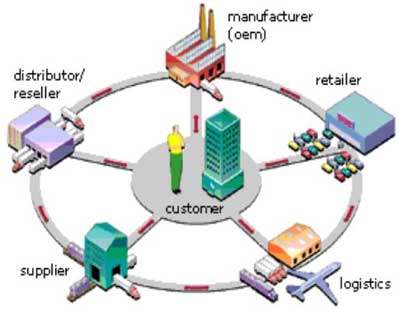

It seems a little early to muse about this, but oh well. What we've learned a little bit about is Supply Chain Management (SCM). Producing and supplying adequate breastmilk for two precociously heavy feeders is not something that comes naturally. And there are constraints. At this point, production is keeping pace with demand, but inventory is a constant problem. The fact that there is a competing shelf-stable product ready at hand when demand exceeds supply is no comfort, because we don't want to lose market share if the consumers develop a taste for the competitor's product. We're shooting for brand loyalty here.

A fairly standard model of SCM is "just in time." Under a Just-In-Time SCM model, you reduce in-process inventory to the maximum extent in order to reduce inventory carrying costs. You engage raw material suppliers who deliver their products exactly as they are needed. And then you ship your product to retailers exactly at the rate that it's flying off the shelves. It's a balancing act. In the world of breastmilk, that means you keep only a day's worth of production in the refrigerator at any given time, and bring a cooler every day. "Just-in-time" SCM is highly beneficial, but it requires constant attention and tweaking. You don't want your manufacturer idled by a hiccup in the raw material supply, and you don't want to leave your retail customers crying for more -- in this case, literally.

But there are confounding problems with the "just-in-time" strategy as applied to this particular product. First, breastmilk must be refrigerated within 4 hours of production, but can only be refrigerated for 24 hours. At the 24 hour mark it must be consumed, frozen, or thrown out. Because production is matching demand basically to a margin of error of a single cc (Nature being a miracle and all), every cc of breastmilk thrown out means there's a cc of formula standing by. Not tragic, but not a desirable result. So, you might say, why not just freeze everything pumped within the first six hours of getting home, and provide the middle-of-the-night stuff and the first-thing-in-the-morning stuff to the nurses in a refrigerated ready-to-eat state? Very clever, and you would be smart to do so, were breastmilk not such a strange commodity. The surface of your skin is loaded with staph and fecal coliform bacteria. (No offense, it just is, and so is everybody's. You'll be happier if you just don't think about it.) Which means your skin contaminates the breastmilk when you pump. (It also gets to the baby when you nurse, but that's what an immune system is for.) But when you pump and immediately freeze the milk, the pathogens in the milk don't get a chance to be beaten to a pulp by the antimicrobial agents naturally occurring in human breastmilk. Those anti-microbial agents need some time to do their dirty work before the milk is frozen. In other words, you're not supposed to freeze the milk until it's a couple of hours old, in order to allow the antimicrobial immunoglobulins and leukocytes naturally occurring the milk to biochemically sterilize it.

Meanwhile, the downside of freezing is that it kills off the immunoglobulins and leukocytes that provide the benefits. So by keeping it cold but not frozen, and then freezing it, you may decontaminate the milk, but not the babies. Fresh is best, but frozen is better than spoilt. So you may need to freeze some, but you can't freeze it immediately, and you shouldn't freeze at all unless you have to in order to keep it from spoiling.

Bah. If only we knew somebody with experience in supply chain management. There's probably some kind of software optimizer for this, if you can afford to buy an ERP solution. I'm pretty sure we won't need the HR and CRM modules, but who knows?